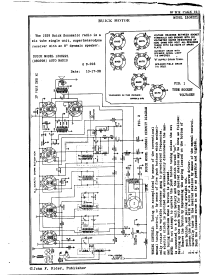

Buick Motor 1308221

| Model: | 1308221 |

| Manufacturer: | Buick Motor (United Motors Service) |

Schematics Content

Page 1:

The 1939 Buick Sonomatic radio is a six tube single unit, super heterodyne receiver with an 8" dynamic speaker,

TUNING CONTROLS: Tuning is accomplished by means of the conventional manual tuning control, or by means of five push buttons which mechanically rotate the variable condenser gang to preselected frequencies. An electric clutch is provided which automatically disconnects the manual tuning mechanism when a button is pressed. NOTE: Do not attempt to operate the push button tuning unless the set is connected to a 6 volt battery and the switch turned "on" Setting up the push buttons for any desired station may be done as follows:

1. Remove the button by depressing the spring located on the bottom of each button, and pulling straight, out.

2. Loosen the screw with a coin or a screw driver.

3. Carefully tune in the desired station by means of the manual control.

4. Push the loosened screw in as far as possible and tighten.

1.

Page 2:

1. Aligning I-F Stages at 260 Kilocycles

(a) Connect the ground lead of the signal generator to the chassis

(b) Connect the signal lead of the signal generator to the grid cap of the 6A8G tube through a 25 mfd. condenser, leaving the grid clip in place.

(c) Connect the output meter across the speaker voice coil.

(d) Set the signal generator accurately to 260 kilocycles and turn volume control on full.

(e) Set the condenser gang to a point at about 600 kilocycles where no station is received.

(f) Adjust the four screws of the two I-F transformers, one on top and one on the bottom of such transformer in the following order ABA and CDC (Illus. 4.8 5 of Figs. 3 & 4) until maximum output is obtained. Repeat these adjustments the second time for greater accuracy using the minimum output from the signal generator which will give a readable indication on the output meter.

(g) CHECKING SELECTIVITY CURVE

The cathode ray oscillograph should be used to check the shape of the I-F curve after completing the "Alignment Procedure". The best tone quality is obtained when both sides of the I-F curve are alike. Slight readjustment of the I-F transformers may be necessary to accomplish this.

2. Aligning at 1560 Kilocycles

The antenna and RF coils contain iron cores which have been very carefully adjusted at the factory. These cores are sealed, and no further adjustments in service are necessary. The Service Replacement coils are also adjusted and sealed at the factory.

(a) Turn tuning condenser plates all the way out and against the high frequency stop.

(b) Set signal generator accurately to 1560 kilocycles and adjust oscillator trimmer (Illus. B, Fig. 3) for maximum output. This trimmer is made accessible by removing plug button, at side of case. Using trimmer alignment wrench, Part No. 7236513. loosen the hex nut with one end and adjust for maximum output by sliding plunger either in or out with the "hook" end of the wrench.

3. Aligning at 1400 Kilocycles

(a) Remove the. 25 mfd. condenser and connect the signal lead of the signal generator through a .0005 mfd. condenser to the Test Plug Part No. 7236514 which is then inserted into the receiver antenna receptacle.

(b) Set the signal generator to approximately 1400 kilocycles.

(c) Rotate the variable plates of the condenser gang until the signal is tuned in with maximum output.

(4) Adjust the R-F and antenna parallel trimmers (illus. F & G, Fig. 3) for maximum output.

4. Aligning at 600 Kilocycles

(a) Set the signal generator to approximately 600 kilocycles.

(b) Rotate the variable plates of the condenser gang until the signal is tuned in.

(c) Adjust the oscillator coil iron core aligning screw (Illus. A, Fig. 3) while rocking the condenser gang back and forth through the signal until maximum output is obtained. This screw is made accessible by removing plug button at side of case.

(d) Repeat adjustments made under "Aligning at 1400 Kilocycles".

SERVICING AUTOMATIC TUNER

1. LUBRICATION

The mechanical parts of the push button tuner should be carefully lubricated as a part of every service job, using a special lubricant which in supplied under Part No. 7236515.

NOTE: Do not use ordinary oils or greases on the automatic tuner.

Grease the following points:

(a) Dial pulleys and pine.

(b) Plunger guides and pinions

(c) Pinion Rack

(d) Manual tuning shaft bearing.

(g) All gears and worms.

(f) Pointer guide.

(a) Clutch shaft bearings.

Do not grease the parkerized cam or brake shoe.

The capacity of the running board antenna is approximately 550 microfarads or .00055 microfarads.

2. SERVICE HINTS.

(a) Improper operation single button.

Sticking cams. Remove knob; loosen screw, force in and rotate the manual tuner knob to grind in. Do not lubricate.

(b) Improper operation - all buttons.

Back lash between condenser drive gears.

Remove automatic tuner assembly by removing the three fastening screws on the underside of case. Loosen the four tuner mechanism to condenser gang mounting screws and adjust the mesh between the two large drive gears, to be as tight as possible without binding.

(c) Replacing button re-set screw hold-on spring.

In cases where it does not seen advisable to replace the complete tuner mechanism, the hold-on spring may be replaced as follows:

The spring can be removed from the pusher arm by prying off with a screwdriver. This operation straightens out the staking, and does not destroy the metal of the pin. Carefully file the burrs off the stake end of the pin. New springs (Part No. 7235845) can be placed over the pins and restaked in place.

(d) clutch.

Do not attempt to disassemble the clutch. If trouble is encountered with this unit, replace with Part No. 7236984.

The antenna circuit in the receiver is designed to operate either with the running board antenna or with a low capacity antenna such as the side cowl type, the selection being controlled by the internal wiring of the antenna lead plug.